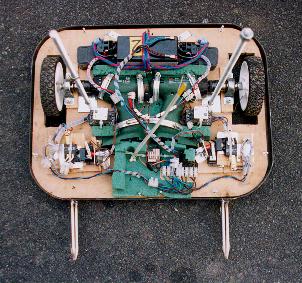

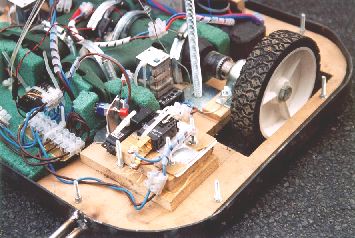

Here's the base of Slippery Strana, already well populated. Beautifully engineered, you must agree!

That giant ball bearing is a tough conveyor-belt component and gives Slippery Strana the freedom to spin on the spot and zoom in either direction on a whim. A bit noisy though.

The black angle-iron you see folded around the edge took hours to cut and bend, and was an ideal place to weld our 'mark 1' spikes. Sadly though, the spikes fell off one by one in our field trials and as you can read elsewhere, we even had to remove the hard earned rim to stay within our weight limit.

(Click the picture for a bigger view)